4 Major VR Benefits in the EV industry

Virtual reality (VR) is a technology that is increasingly being used to accelerate the development of electric vehicle (EV) manufacturing. By using virtual reality, manufacturers can simulate the assembly line process and identify potential bottlenecks or issues before they occur in the real-world. This allows for more efficient and streamlined production, reducing the time and cost required to bring new EV models to market.

Another key advantage of using VR in EV manufacturing is the ability to provide specialized training for workers. With VR simulations, workers can practice and perfect their skills in a virtual environment before applying them on the assembly line. This can help to reduce errors and improve overall efficiency.

VR technology is also being used to improve equipment maintenance and troubleshooting in EV manufacturing plants. By creating virtual replicas of the assembly line, manufacturers can use VR simulations to identify and diagnose problems with equipment in real-time, without having to shut down the production line. This can help to minimize downtime and increase overall production capacity.

Additionally, VR technology can also be used to provide virtual tours of EV manufacturing plants to stakeholders and customers. This allows them to see the production process in action and understand the technology and engineering behind the vehicles, without having to visit the physical plant.

Below are 4 major areas where VR is impacting the EV manufacturing industry:

1. Simulating the Assembly Line Process

There are a few different ways to simulate an assembly line process using virtual reality, but some common approaches include using VR software and hardware to create a virtual replica of the assembly line, using VR simulations to train workers on how to perform specific tasks on the assembly line, and using VR to visualize and analyze production data and optimize the assembly line process.

Some specific tools that can be used include VR headsets and controllers, 3D modeling and animation software, and game engines like Unity or Unreal Engine. Additionally, sensors can be added to the assembly line to track real-world data and feed it into the VR simulation, allowing for a more realistic and accurate representation of the assembly line process.

2. Specialized Training

VR can be used to train employees on the use of specialized equipment and tools, such as welding machines and robotic arms, which can be dangerous if used improperly. By using VR, employees can learn how to use the equipment safely without the risk of injury.

There are several benefits of using virtual reality (VR) to train employees working in an electric vehicle (EV) manufacturing plant, with a focus on the use of specialized equipment and tools such as welding machines and robotic arms.

- Increased safety: By using VR to train employees on the use of specialized equipment and tools, such as welding machines and robotic arms, the risk of injury from improper use is reduced. VR allows employees to practice using the equipment safely without the risk of injury.

- Improved efficiency: VR can be used to simulate different scenarios and conditions, allowing employees to become familiar with the equipment and learn how to use it efficiently. This can help reduce downtime and improve the overall efficiency of the manufacturing process.

- Reduced costs: Training employees using VR can be less expensive than using physical equipment, as there is no need to purchase or maintain the equipment.

- Flexibility: VR can be used to train employees on different variations of the equipment and tools, which allows employees to be prepared for any situation that may arise in the actual manufacturing process.

- Better understanding of the process: VR can provide a more immersive and interactive experience, which can help employees better understand the process of using the specialized equipment and tools and make them more confident in their abilities.

- Simulating realistic scenarios: VR can simulate realistic scenarios that are difficult or impossible to replicate in the real world, this can help train employees on how to handle emergency situations or rare events that may happen in the manufacturing process.

- Remote training: Employees can be trained remotely by using VR, this can be beneficial for companies that have employees working in different locations or for employees who are unable to travel to a training facility.

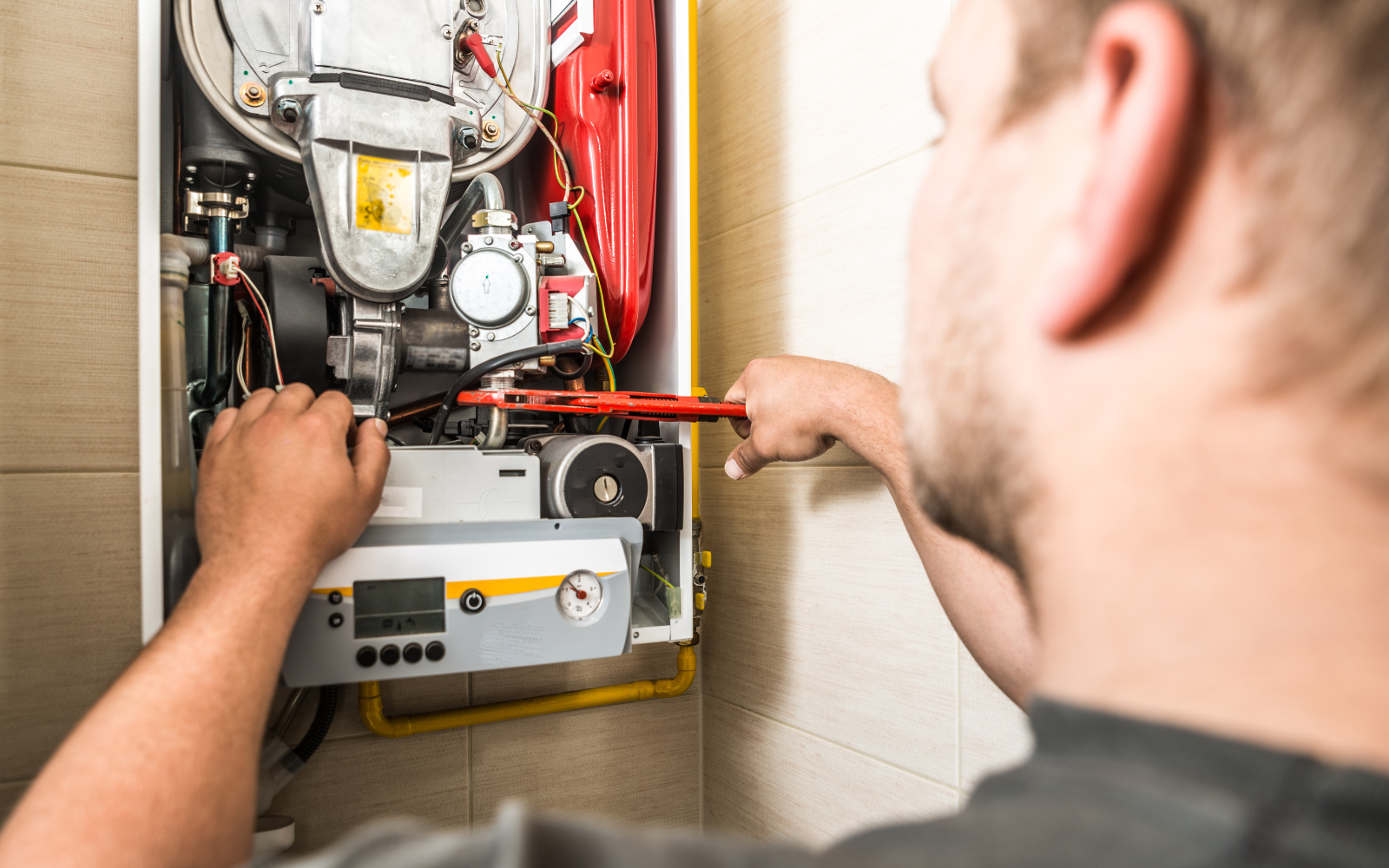

3. Equipment Maintenance & Troubleshooting

Traditional maintenance and troubleshooting in a vehicle manufacturing plant can be hindered by a lack of real-time data and visibility into the production process, which can lead to delays in identifying and addressing issues.

Manual processes for maintenance and troubleshooting can be time-consuming and prone to errors, and may not be able to keep up with the fast pace of production. Depending on the age of the plant, traditional equipment may not be designed to allow for remote monitoring and diagnostics, which can make it harder to identify and solve problems.

By using VR to train employees on the maintenance and troubleshooting of equipment, you can reduce downtime and improve the overall efficiency of the manufacturing process.

In summary, using virtual reality for training employees on the maintenance and troubleshooting of the equipment in an EV manufacturing plant can provide a safe and cost-effective way to improve the efficiency, safety, and reliability of the manufacturing process.

4. Virtual Tours

Having the ability to give virtual tours of the plant to new employees can help them familiarize themselves with the facility before they start working.

Virtual tours also allow existing employee's to retrain anytime there are worksite changes. Using VR to give tours of an electric vehicle manufacturing plant can provide several benefits:

- Immersive experience: VR can provide a more immersive and interactive experience, allowing potential customers or new employees to feel as if they are physically present in the manufacturing plant and experience the facility in a way that is not possible through traditional 2D tours or videos.

- Portability: VR tours can be accessed from any location and at any time, which can be beneficial for customers who are unable to travel to the facility or for employees who are working remotely.

- Cost-effective: Creating a virtual tour of the manufacturing plant can be less expensive than maintaining a physical tour of the facility, and it can be easily updated and improved over time.

- Safer training: VR tours can be accessed safely from anywhere with an internet connection. This removes the risks from potential worksite hazards.

- Environmental friendly: Because these tours are digital and don't require any physical movement to access, this can be beneficial for companies that are looking to decrease their carbon footprint.

Overall, using virtual reality to give tours of an electric vehicle manufacturing plant can provide a cost-effective, safe, and immersive way to showcase the facility to potential customers or new employees.

Click to share this article

Transform your business with immersive technologies

Schedule a consultation to see how BSD can help your organization unlock new avenues of engagement.

CONTACT US

Global Headquarters

1555 Dublin Avenue, R3E 3M8

Winnipeg, MB, Canada

PUBLIC RELATIONS

DIVISIONS

GENERAL

IN THE SPIRIT OF RECONCILIATION

We would like to acknowledge that the land on which we gather is Treaty One Territory, the home and traditional lands of the Anishinaabe (Ojibwe), Ininew (Cree), and Dakota peoples, and in the National Homeland of the Red River Métis. Our drinking water comes from Shoal Lake 40 First Nation.

Join 10,000+ people who get XR tips, insights, and company updates monthly.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Privacy Policy Accessibility Sitemap Support

Bit Space Development Ltd.